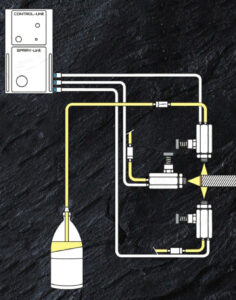

The Protective Agent must be sprayed on the pressure rollers in order to protect them from adhesive residues sticking on them and preventing the edges from being stained or marked.

Certain edging manufacturers are incorporating a protective film on their edges to protect them in the edging process, the problem is that the blades of the machines normally damage this protective film, lifting it from the edge. To avoid this, by using the Protective Agent, it is possible to provide the edge with a film that helps the plastic to slide on the blades and not rise.

Visible advantage: Absolute cleaning of the pressure rollers of adhesive residues. Edge protector film in perfect condition at the end of the edging process.

| REFERENCE | LC-BLUE |

| CARAFE | 25 lt. |